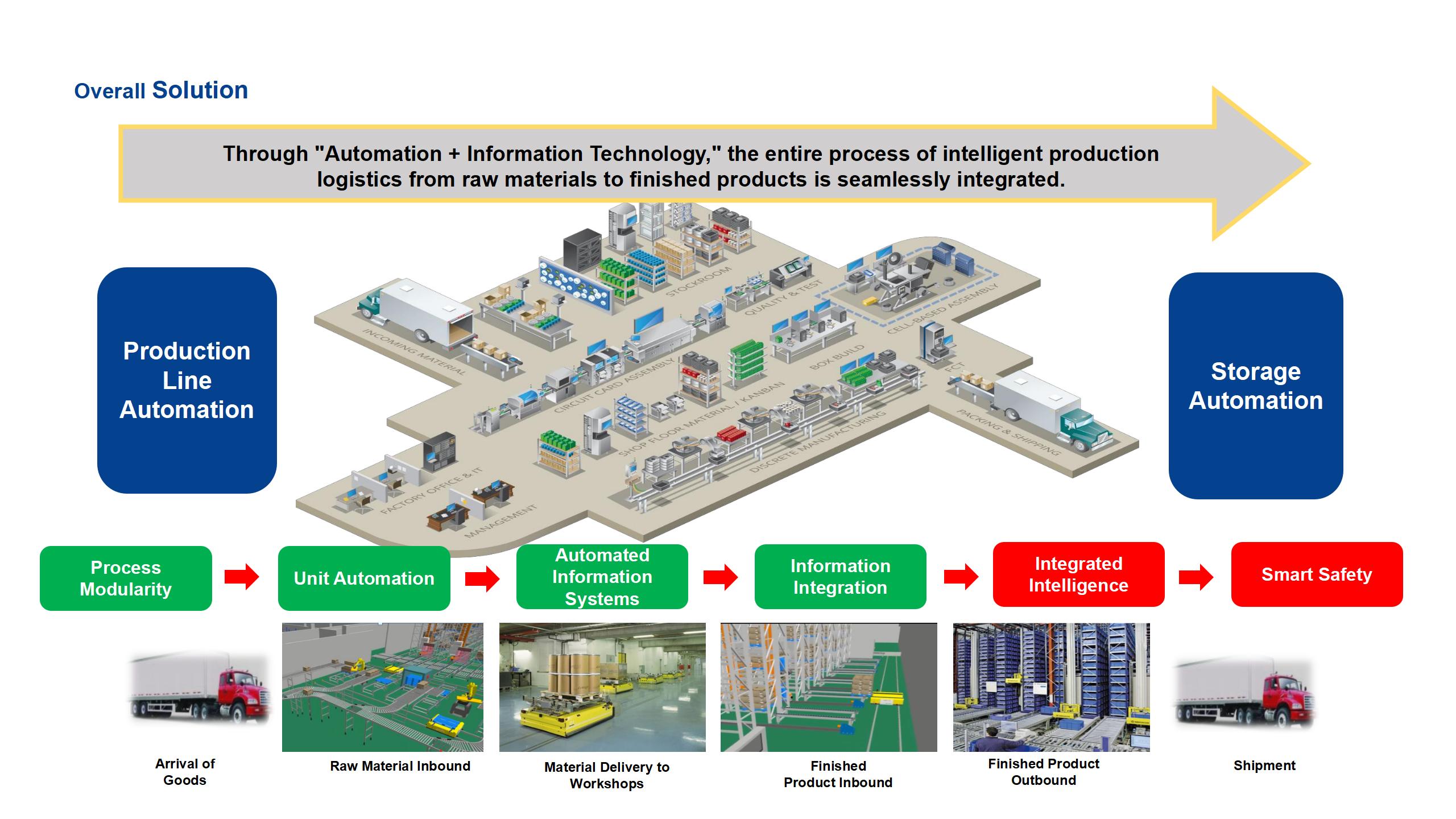

It aims to build an efficient and intelligent automotive semiconductor whole plant logistics system, relying on automation and intelligent technology to realize the seamless connection between the production and logistics processes. Through AGV autonomous navigation, task scheduling optimization, dynamic path adjustment, and other technologies, it improves handling efficiency, reduces labor intensity, and minimizes operational errors. The system uses IoT to enable equipment monitoring and predictive maintenance, ensuring efficient and stable operation. Through lean production, data-driven decision-making, and real-time visualization and transparency of logistics information, the system optimizes logistics costs and space utilization, supports flexible production, and helps Party A achieve benchmark operations in semiconductor warehousing and logistics through intelligent upgrading.